We produce the Mod70 hydrofoils for the trimarans in this fast, offshore sailing class. Teams Argo Racing and Beau Geste Racing already sail with uptip L-foils designed by Martin Fischer. In cooperation with Andrew MacPherson (Macca) two sets of foils have already been developed and shipped.

Ultra-modern

Lighter = better

Foiling

Craftsmanship

MOD70 HYDROFOILS - DESIGN

We build your new foiling boat!

MATERIAL & TECHNOLOGY

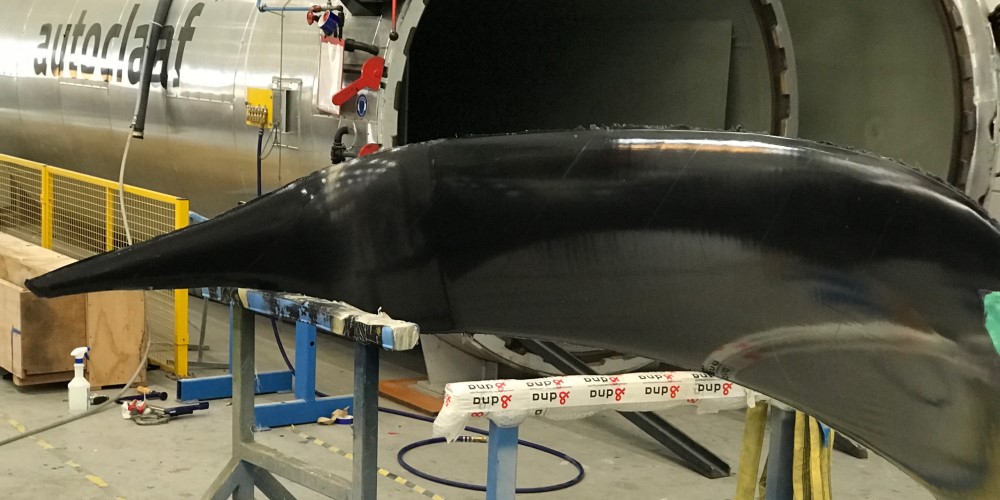

Basic material: the foils are made of carbon pre-preg. The Mod70 hydrofoil models are milled from the 3D-file and Autoclave-resistant carbon tooling is made. With our unique ‘one-shot’ production process, we manufacture all our continuous fiber foils under vacuum cured in our Autoclave.

The production method specially developed for this purpose creates a hydrofoil that cures in one go, without glue joints and including internal stiffening ribs. The result is a super-strong hydrofoil that is as light as possible.

The pre-cutting process of laminates is done by our automated pre-preg cutting machine of the brand Zünd. This process ensures excellent product quality and constant product weight.

For the Mod70 hydrofoils, the board up and down facilities in the foils are also fitted.

CHARACTERISTICS MOD70 HYDROFOILS

Length: 3.40 m

Foil-tip-length: 1.35 m

Width: 0.56 m

The above specifications refer to the daggerboard foils.